Production Facilities

Steel Window Manufacturing Facility: Precision Craftsmanship, Industrial Excellence

1. Advanced Production Technology for Unmatched Quality

At the core of the steel window manufacturing facility, hot-dip galvanized steel coils are transformed into rugged, corrosion-resistant window frames using cold-bent single-frame technology. The laser welding systems ensure airtight, bubble-free seams on every steel window profile, achieving military-grade precision for structural integrity and thermal efficiency.

![]()

2. Rigorous Quality Control Meeting Global Standards

Every batch from the steel window workshop undergoes 12-stage inspections, from raw material audits to stress tests. The steel fabrication facility employs 3D scanners to verify frame dimensions, while pressure chambers simulate hurricane-force winds and -40°F freeze-thaw cycles to validate durability. The fluorocarbon-coated steel windows are tested for UV resistance and abrasion resilience. The steel window manufacturing plant guarantees compliance with EU, US, and AU building codes, including fire ratings (up to 90 minutes) and seismic requirements.

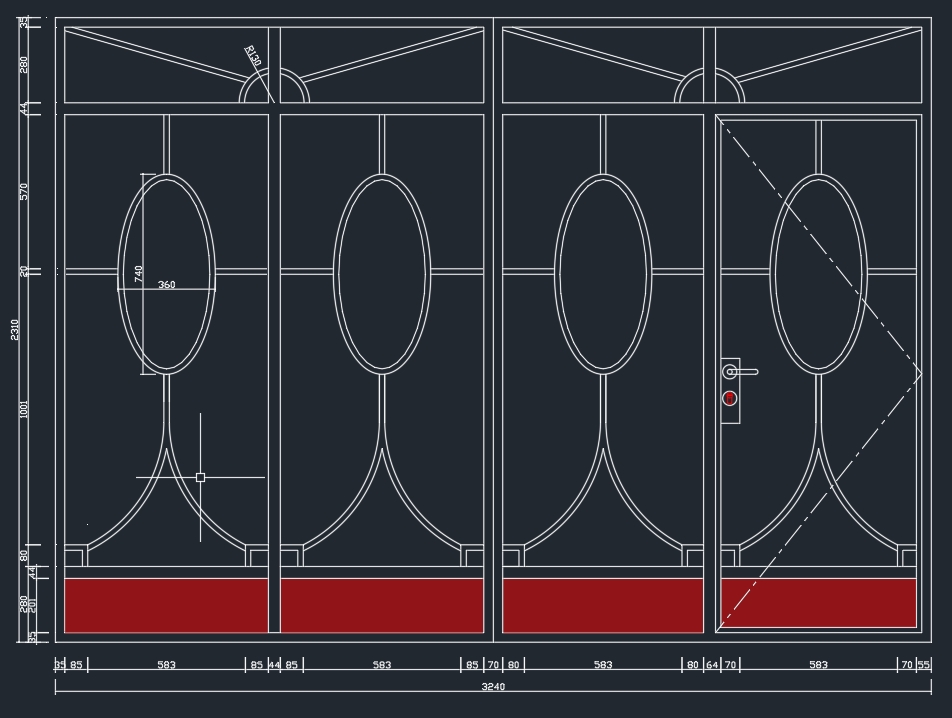

3. Custom Engineering Solutions

The steel window manufacturing workshop combines artisanal craftsmanship with digital agility. Designers collaborate to create bespoke steel windows—whether French arched muntins, industrial riveted grilles, or mid-century geometric grids. The steel fabrication facility’s laser cutters handle complex patterns (0.5mm precision), while modular jigs enable rapid style transitions between Art Deco and farmhouse collections.